Protect Your Brand and Customers with Noise-Compliant CSAM & WAAM Cells

When a cold spray or wire arc cell exceeds noise limits, your customer doesn’t blame « the acoustic enclosure vendor »—they blame the name on the machine. If your system isn’t quiet and compliant out of the box, it’s your reputation on the line.

Without engineering controls, neither process comes close to meeting workplace noise regulations:

The Compliance Gap

High-pressure cold spray generates 110–120 dBA near the nozzle. Arc-based WAAM runs at 95–105 dBA. OSHA’s action level sits at 85 dBA, with the permissible exposure limit at 90 dBA for an 8-hour shift.

The math is straightforward: at these noise levels, operators can work minutes, not full shifts, without hearing protection, and engineering controls like acoustic enclosures are OSHA’s first-line requirement before PPE.

The question isn’t whether your metal AM cell needs noise control. It’s who owns that scope, and what happens when it doesn’t perform.

MECART designs and manufactures noise enclosures for the noisiest industrial processes—since 1974. We deliver cold spray soundproof booths and WAAM noise enclosures that integrate directly with your equipment, so you can hand over a complete, noise-controlled metal AM cell with confidence.

On this page

Planning your first enclosure?

Our design checklist helps you define requirements before the first conversation—noise targets, access needs, penetrations, and more.

No commitment. Takes 5 minutes.

The noise problem is clear. But who carries the risk—and what happens when the enclosure scope falls short?

OEMs & Integrators: What’s Really at Stake

Whether you’re an OEM or a systems integrator, your customer sees one metal AM cell with your logo on it. If the enclosure doesn’t perform, you own the problem in their eyes. Your customers expect:

- A noise-controlled cell where cold spray/WAAM, dust collection, robotics, and controls work as one system

- Clear accountability when something isn’t right

- A solution that meets workplace health & safety regulations (OSHA, NFPA, AHJ expectations)

When the enclosure scope is weak or poorly coordinated, the impact is direct:

- Failed inspections put the entire cell on hold

- Emergency rework eats into your margins and engineering time

- The customer starts to question your expertise, even if the issue came from a generic box supplier

You already have enough to manage—process performance, throughput, integration, commissioning—without worrying whether the noise enclosure will hold up.

You own the metal AM cell. We own the acoustic enclosure that helps keep it safe, quiet, and inspection-ready. You don’t need “a box” around the noise.

You need an acoustic partner who focuses on the enclosure scope, understands cold spray and WAAM hazards, speaks the same language as your team, and helps protect both your customer and your reputation.

Ready to Take the Enclosure Scope Off Your Plate?

Whether you’re standardizing a product line or building a one-off metal AM cell, MECART owns the enclosure so you can focus on performance, integration, and throughput.

No generic boxes — every enclosure is engineered to your process, noise targets, and layout.

Why Partner with MECART for CSAM & WAAM Enclosures

MECART is a North American manufacturer of modular acoustic enclosures and buildings. Since 1974, we’ve delivered more than 4,000 custom noise-control and controlled-environment projects across industrial, manufacturing, commercial, and metal AM applications, under an ISO 9001:2015–certified design and manufacturing process.

On CSAM and WAAM projects, our role is simple: We take ownership of the acoustic enclosure so your cell runs quietly, safely, and in line with your customer’s requirements.

So when you hand over the metal AM cell, the enclosure is the one part nobody has to worry about.

Premium Acoustic Performance

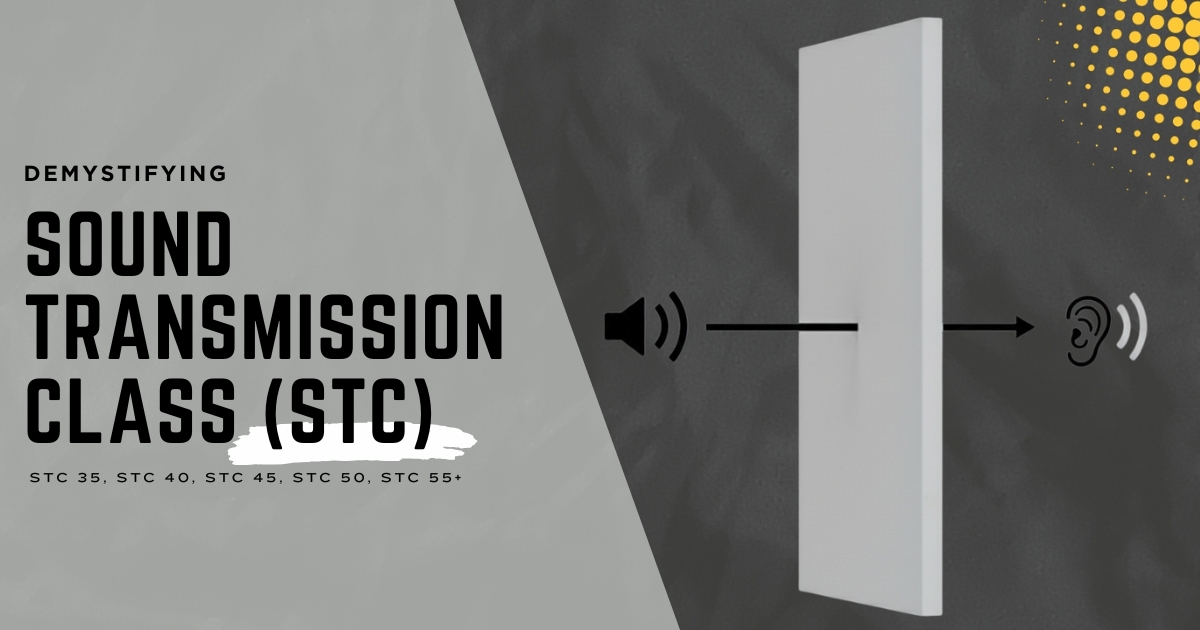

STC ratings from STC 35 to STC 62 (up to STC 72 with double panel configuration)

Compliance at 90 dBA is the baseline—our acoustic enclosures can take you much lower. You choose the target noise level based on how much extra safety and comfort you want to offer

Our components are laboratory tested to established acoustic standards (ASTM E90 / E413), providing proven performance, with charts available upon request

Panel Systems & Interior Finishes

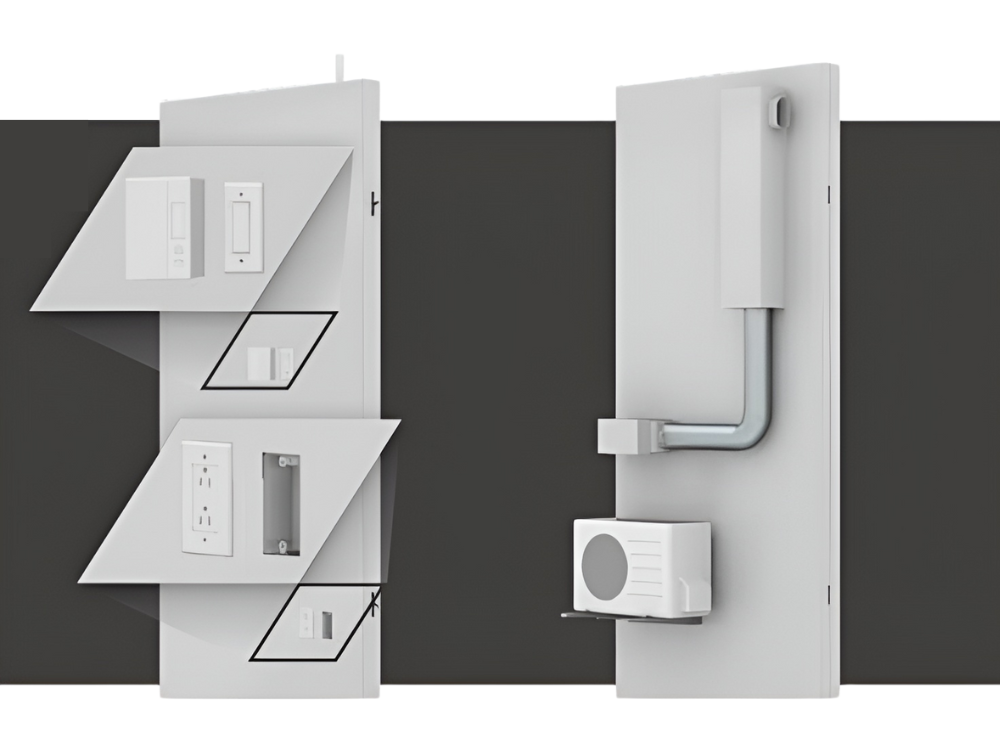

Modular soundproofed panels with heavy-gauge steel and an engineered core.

Utilities are integrated directly into the modular panels, minimizing footprint and on-site work while delivering a cleaner, more attractive space.

You can specify perforated sound-absorbing panels for enhanced sound control, or smooth non-perforated steel interiors for combustible-dust zones that still satisfy noise regulations.

Dust Collection, Ventilation & Hazardous Areas

Enclosures engineered to accept your dust collection and make-up air while maintaining acoustic performance

STC-rated silencers and sealed penetrations

Details and options that support NFPA 484 / Class II Div 1, Group E needs, including hazardous-location electrical and lighting when required

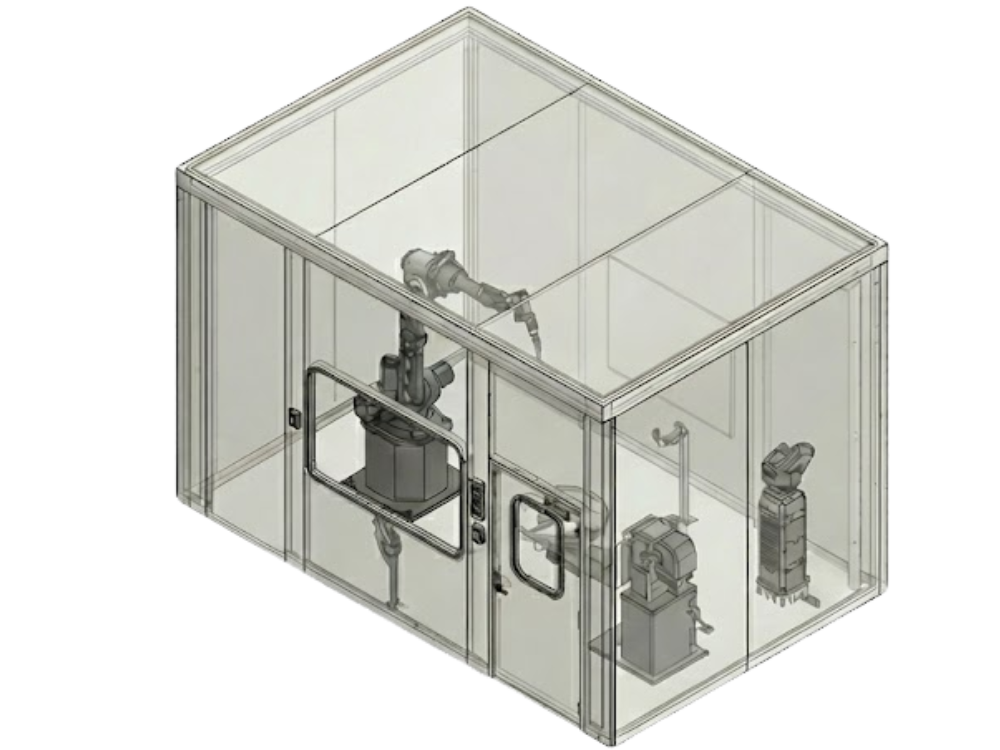

Custom Design: Integration With Your Metal AM Cell

Custom pass-throughs and openings for robots, cranes, extraction plenums, utilities, controls and cable trays

For OEMs, we design standardized custom enclosures that can be integrated and repeated across your product line; for integrators, we deliver contract-based enclosures tailored to each unique metal AM cell

Enclosures designed around your specific CSAM or WAAM layout, not the other way around

These capabilities only matter if they fit your project. Tell us what you’re working on—we’ll confirm if we’re the right partner.

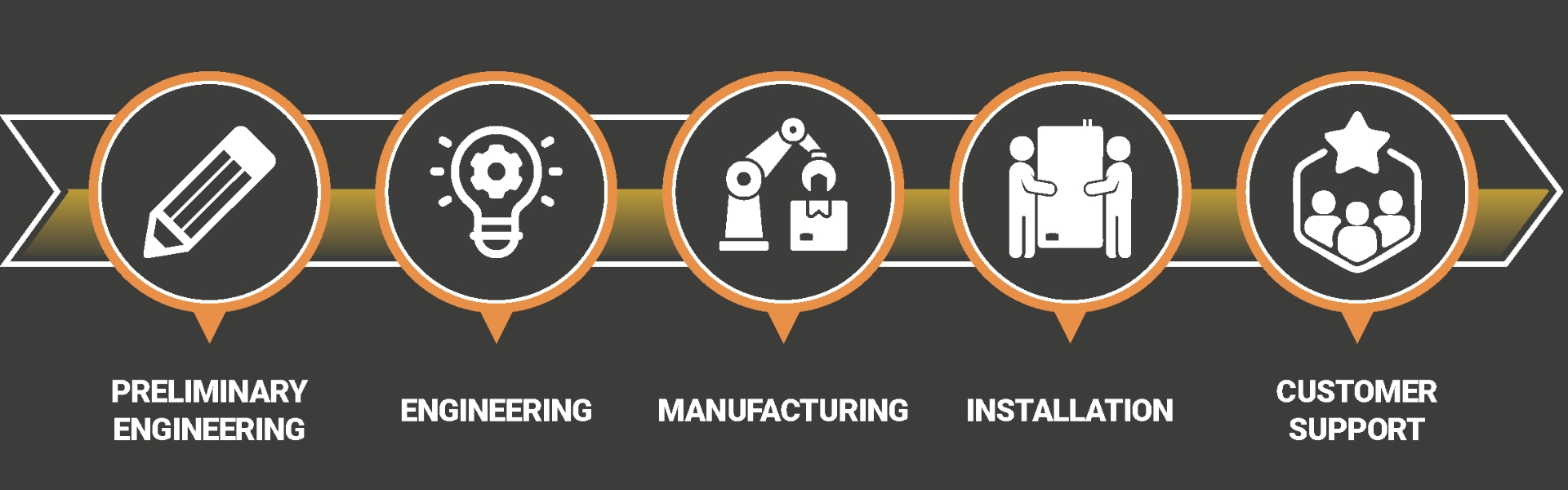

How We Work with OEMs & Integrators: A 4-Step Plan

We treat the enclosure as a core part of your metal AM cell, from early noise targets to final installation.

Discover

We start with your process and constraints:

- Cold spray additive manufacturing (CSAM) or wire arc additive manufacturing (WAAM)

- Expected noise and desired exterior dB

- Combustible dust considerations

- Facility constraints

- Timeline

- Preferred installation model

Design & Budget Quote

Within a few business days, we provide:

- Preliminary booth dimensions and STC / noise-control recommendations

- Budget pricing suitable for RFQs and proposals

- A clear base scope with options (e.g., hazardous-rated components, special penetrations)

Once awarded, we refine drawings, details and interfaces so the enclosure fits your mechanical, electrical and process design.

Build & Test

At our ISO 9001 certified facilities, we:

- Fabricate modular panels and structural components

- Integrate doors, windows, lighting and options

- Perform quality checks before shipment

Deliver, Install & Support

We adapt to how you work:

- Turnkey install by MECART

- Supervised install with your crew

- Self-install with your crew or the 3rd-party installer of your choice

We can deliver fully preassembled enclosures or they can be installed directly on-site.

Ready to Start Step 1?

We’ll provide preliminary dimensions, STC recommendations, and budget pricing within days—no commitment required.

Case Studies: How Our Enclosures Perform in Real Metal AM Cells

You’ve seen how we work in four steps—from discovery through design, build, and installation. The next question is simple: what does that look like on a real metal AM cell?

In both projects below, the enclosure was engineered as part of the cell layout: STC-rated wall and roof panels, planned penetrations for dust collection and ventilation, and integrated doors, windows, lighting and electrical services.

The WAAM enclosure at Polycontrols and the CSAM enclosures for Titomic show how the same modular building blocks can be tuned to very different metal AM processes while keeping noise control, access, and integration under one roof.

Featured Case Study

Two different metal additive manufacturing processes. Two different noise profiles. Same modular system, adapted to each cell’s layout and requirements.

If you’re evaluating whether this approach fits your project, here’s what usually comes up:

FAQ – Acoustic Enclosures for CSAM & WAAM Cells

Here are the most common questions from OEMs and AM integrators looking to include a noise enclosure with their cold spray or wire arc additive manufacturing cell.

Can the enclosure be customized to fit our layout?

Yes. Every enclosure MECART delivers is custom-designed around your machine layout, access needs, and facility constraints. We’ll adapt the size, configuration, openings, and penetrations to your process requirements. Learn more about our custom machine enclosure capabilities.

How do operators access the machine once it’s enclosed?

We design doors, windows, and access hatches based on your operator routines and maintenance workflow. Options include STC-rated acoustic doors (double swing, sliding, or bi-fold), vision panels, and overhead clearance for cranes.

How is ventilation, fume extraction, or cooling handled?

We have in-house HVAC experts who can design a solution for your needs, or we can collaborate with your team. We provide STC-rated silencers, grilles, plenums, and sealed penetrations so you can connect supply/exhaust without acoustic leakage.

Do your enclosures support combustible metal dust and hazardous zones?

Yes. We design for Class I Div 2 and Class II Div 1 (Group E) where needed. Options include non-combustible panels, smooth surfaces, sealed lighting, rated penetrations, grounding points, and coordination with your safety team.

What materials are used? Will it last in production?

We use 4″ thick modular soundproofed panels with 16-gauge steel and high-density acoustic cores. Panels are non-combustible, impact-resistant, and designed for years of heavy-duty use in manufacturing plants. Our enclosures are engineered to last 25+ years.

How long does it take to receive a noise enclosure?

We’ve delivered enclosures on schedules ranging from expedited turnarounds to multi-phase roll-outs. What matters most is alignment upfront—once we understand your noise targets, layout, and deadline, we’ll confirm capacity or recommend adjustments to hit your date. Early coordination means fewer surprises. Let’s discuss your timeline.

Can the enclosure be relocated or reconfigured?

Yes. MECART enclosures are modular and relocatable. Panels, penetrations, and utilities can be reconfigured or expanded as your production needs evolve, without having to rebuild from scratch.

How much does a custom acoustic enclosure cost?

Cost depends on size, acoustic performance (STC rating), sound absorption needs, options (lighting, electrical, airflow), delivery fees, and installation method, amongst other things. Custom projects have custom prices, but if you are looking to do a business partnership and create a »repeat » enclosure for volume, we can create a standard solution for you with a fixed price. Contact us to learn more about our prices.

Guides, Tools & Resources for OEMs & Integrators

Demystifying STC Ratings: STC-35, STC-45, STC-52

How to pick the right STC rating for my project.

What Is Industrial Noise & How to Control It

OSHA limits, exposure, and why engineering controls come first.

8 Key Elements of a High-Performance Acoustic Enclosure

Panels, seals, penetrations, and silencers done right.

MECART Modular Panel System

Fast installs, clean interfaces, relocatable by design.

Ready to Protect Your Customer—and Your Brand?

We started this page with a simple truth: when a cold spray or wire arc cell exceeds noise limits, your customer doesn’t blame the enclosure vendor; they blame the name on the machine.

A well-engineered enclosure changes that equation. The cell starts on time, passes inspection, and operators can work safely. The enclosure becomes invisible—and that’s exactly what you want.

With 50 years of modular acoustic experience and real CSAM/WAAM projects behind us, MECART is the partner who makes that happen.

Ready to Plan Your Next CSAM or WAAM Enclosure?

Get exactly what you need for your metal AM cell—clear pricing, a technical brochure for your team, and a practical checklist to scope the enclosure right the first time.

No generic boxes — every MECART enclosure is engineered to your process, noise targets, and layout.