Does Mining Cause Noise Pollution? If So, What Is It?

Does mining cause noise pollution? A resounding yes. By definition, pollution is the introduction of harmful or disruptive elements into the environment, and mining noise is exactly that.

So, what is mining noise pollution? It covers all unwanted, disruptive sounds generated throughout the mining cycle that can damage human health, stress wildlife, disrupt ecosystems, strain community relations, and carry serious financial consequences, from lost productivity to costly settlements. In short, it’s a complex hazard no mining operation can afford to ignore.

Noise Pollution from Mining: 4 Noise Source Types Explained

The noises are mostly generated by mining machinery, equipment, blasting operations, crushing, and other processes. These sounds can be grouped into 4 main source types, each with distinct characteristics. [Manwar et al., 2016]:

- Point Sources: These are single, concentrated sources of noise, like a specific machine operating in one spot. In mining, examples include drilling machines and shovels.

- Line Sources: Noise that emanates continuously along a length or path. A common example in mining is the use of conveyor belts.

- Area Sources: Noise that comes from a larger, spread-out region rather than a single point or line. Crusher plants in mines are typically categorized this way.

- Moving Sources: These are sources that generate noise while changing their location. Dumpers traveling on haul roads are a prime example in mining operations.

Each category plays a role in cumulative mining noise pollution, shaping the overall noise profile of a mine. Combined, noise levels often exceed occupational safety limits, putting miners at significant risk of hearing damage and other health effects.

Health Impacts of Noise Pollution on Mine Workers

Hazardous noise exposure is more common in mining than in any other major U.S. industry. According to NIOSH (CDC), the statistics related to mining noise pollution and NIHL are alarming:

- 3 out of 4 miners (76%) work in areas where the average noise level is above 85 dB, loud enough to cause gradual hearing loss.

- 1 out of 4 miners (25%) are exposed to levels above 90 dB, which can damage hearing even faster.

- Peak noise levels can reach 120 dB in mining environments.

Most miners spend their shifts surrounded by noise capable of damaging hearing, sometimes almost instantly. But hearing loss is only part of the story. Prolonged or intense exposure to noise affects the body through both direct pathways (damage to the auditory system) and indirect pathways (activation of the nervous and hormonal stress responses). These effects can be separated into two categories: auditory health effects and non-auditory health effects.

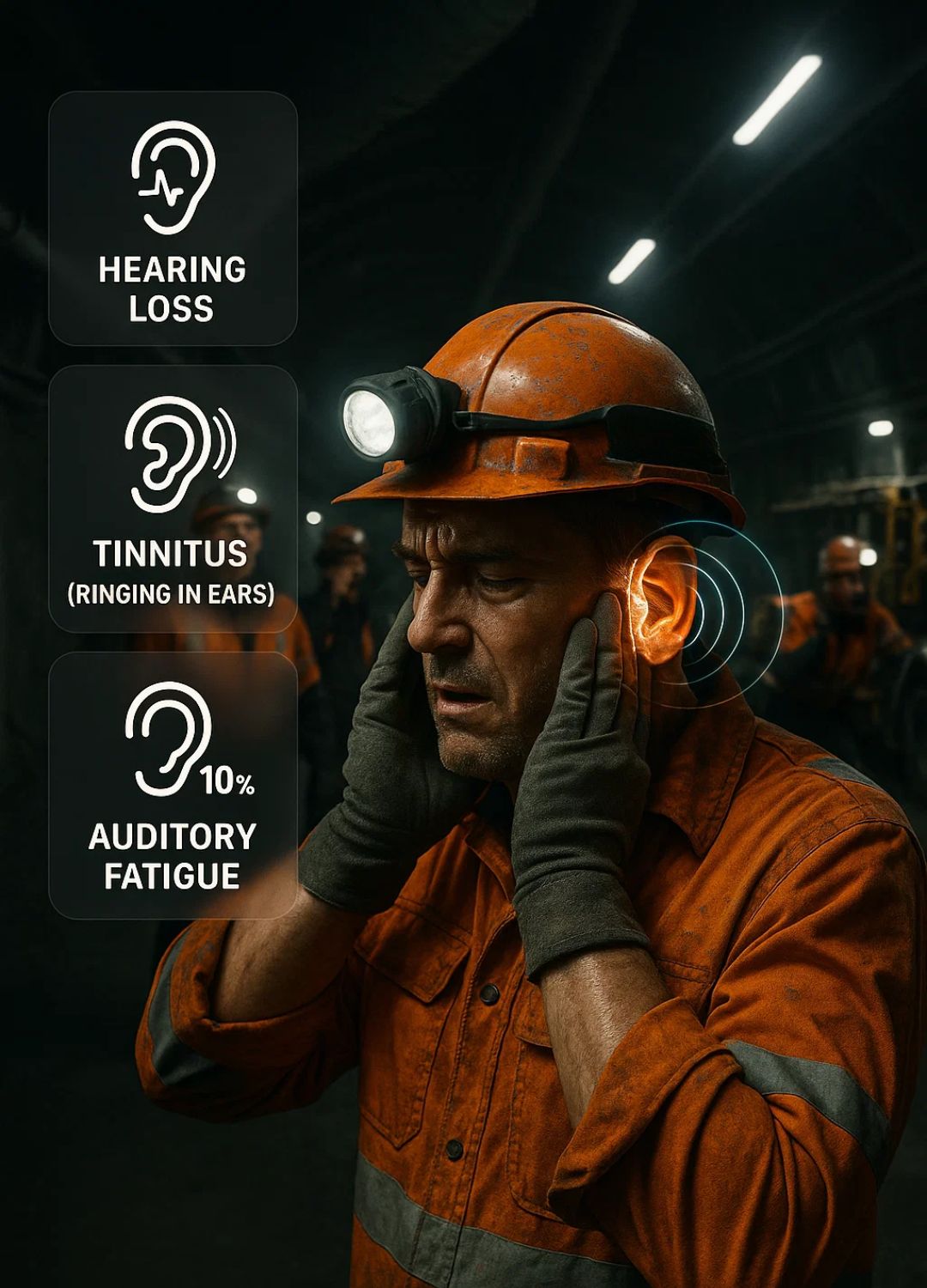

Auditory Health Risks from Noise Pollution in Mining Operations

Noise-induced damage to the auditory system remains the most documented consequence of noise exposure. Its effects are dose-dependent, influenced by factors such as intensity, duration, frequency, and individual susceptibility factors, including age, smoking, and genetic predisposition.

Noise-Induced Hearing Loss (NIHL)

The most prevalent occupational hearing disorder, caused by repeated exposure to levels >85 dB(A) or single impulse events. Early signs appear as high-frequency hearing loss (3–6 kHz), progressing with continued exposure.

Tinnitus and Hyperacusis

Tinnitus is a persistent ringing or hissing after noise exposure; it can become chronic and affect quality of life. Hyperacusis is a heightened sensitivity to everyday sounds, where sounds that others perceive as normal seem uncomfortably or unbearably loud, accompanied by symptoms such as pain, fullness, or pressure in the ears.

Auditory Fatigue and Communication Difficulties

Noise can cause a temporary reduction in hearing sensitivity, making it difficult to hear safety warnings and communicate effectively, which increases the risk of accidents.

Non-Auditory Health Risks from Noise Pollution in Mining Operations

Noise exposure triggers a systemic stress response, activating the hypothalamic-pituitary-adrenal (HPA) axis and sympathetic nervous system, leading to hormonal, cardiovascular, cognitive, and immune consequences.

Cardiovascular and Metabolic Effects

Hypertension, arrhythmia, ischemic heart disease, and stroke are strongly linked to chronic noise exposure. Long-term exposure correlates with increased blood glucose, lipid changes, and metabolic syndrome.

Sleep Disturbance and Insomnia

Noise delays sleep onset, fragments sleep, and reduces REM cycles, leading to fatigue, cognitive decline, and emotional dysregulation.

Cognitive and Psychological Effects

Chronic exposure impairs concentration, memory, and problem-solving. Annoyance, stress, depression, and anxiety are prevalent, and it is also linked to dementia.

Immune and Endocrine Dysregulation

Noise triggers stress hormone release (catecholamines, cortisol), which can weaken immune response and contribute to systemic inflammation.

Quiet the Mine. Protect Workers.

Noise Sources in Mines and Mining Plants

Effective noise control solutions in mining start with a clear understanding of where the noise comes from and how loud it actually is. A mine’s soundscape is complex, and choosing the right solution for protecting workers from hazardous mine noise pollution requires careful monitoring. Noise levels from any single piece of mining equipment are not fixed. They vary with multiple factors such as:

- Equipment manufacturer and model

- Maintenance condition

- Distance between the source and workers

- Type of mining environment (underground vs. open-pit)

- Vibrations emitted

Because of these variables, noise readings are best expressed as a range to reflect real-world conditions rather than lab-perfect values. The table below presents typical mining equipment noise levels in dBA, based on published measurements in operational mines.

Mining Equipment Noise Levels (dBA) — How Loud is the Machinery?

Values below are typical ranges measured in operating mines. Actual levels vary with make/model, maintenance, distance, and duty cycle. Use these as screening estimates; confirm with site measurements before selecting controls.

|

84–120 dBA

Fans (incl. Auxiliary Fans)

Mine ventilation; airflow, blades, motor vibration.

Babich & Bauer (2006); McBride (2004)

|

78–116 dBA

Shuttle Cars

Ore haulage; engine, hydraulics, ore impacts.

Babich & Bauer (2006); Amosu (2021, IJPE)

|

|

118 dBA

Kilns

Ore processing; burners, fans, rotating shell.

Amosu (2021, IJPE)

|

93–115 dBA

Drills

Rock boring; percussive blows, rotation, high-pressure air.

Babich & Bauer (2006); Amosu (2021, IJPE)

|

|

107 dBA

Rod / Ball Mills

Ore grinding; tumbling balls, drum rotation, impacts.

Amosu (2021, IJPE)

|

72–107 dBA

Trucks & Quarry Trucks

Haulage; engines, exhaust, tires/road, vibration.

McBride (2004); Amosu (2021, IJPE)

|

|

90–107 dBA

Crushers (Primary, Jaw, Tertiary)

Rock reduction; crushing and material impacts.

Amosu (2021, IJPE)

|

100 dBA

Draglines / Shovels

Overburden excavation; engines, hoist/drag friction.

Amosu (2021, IJPE)

|

|

72–106 dBA

Scrapers / Graders

Levelling & earthmoving; engine, scraping, hydraulics.

McBride (2004); Amosu (2021, IJPE)

|

105 dBA

Chutes

Guides ore/coal; falling material, metal impacts.

Amosu (2021, IJPE)

|

|

91–101 dBA

Dozers / Bulldozers

Pushing earth/rock; diesel engine, tracks, blade-ground.

Amosu (2021, IJPE)

|

95–103 dBA

Loaders / Miner-Loaders / Loader-Dumpers

Scooping & transport; engines, hydraulics, bucket impacts.

McBride (2004); Amosu (2021, IJPE)

|

|

84–102 dBA

Conveyors / Stageloaders / Chain Conveyors

Bulk transport; chain/roller impacts, motors.

Babich & Bauer (2006); McBride (2004)

|

90–100 dBA

Screens & Shake-outs

Sorting by size; vibration, impacts, material flow.

Amosu (2021, IJPE)

|

|

85.1 dBA

Hydraulic Hammers

Rock breaking; percussive blows, hydraulic flow.

Amosu (2021, IJPE)

|

88.8 dBA

Sieve Systems

Classification; vibration and metal-material contact.

Amosu (2021, IJPE)

|

|

90.6 dBA

Jaw Crushers

Primary crushing; rock impact, motor drive.

Amosu (2021, IJPE)

|

89.4 dBA

Tertiary Crushers

Final reduction; crushing and material impact.

Amosu (2021, IJPE)

|

|

73–74 dBA

Excavators

Digging & loading; engine, hydraulics, metal contact.

Amosu (2021, IJPE)

|

75.3 dBA

Band Facilities

Conveyance/support; low noise from rollers/machinery.

Amosu (2021, IJPE)

|

Even at their quietest, many mining machines operate near the 85 dBA threshold where permanent hearing damage can begin. At peak output, they far exceed safe occupational limits.

Now imagine several of these high-decibel sources running side by side — the result is a hazardous cacophony that puts workers at serious risk and demands robust control measures. This is exactly why comprehensive regulatory standards exist for mining noise pollution.

Recognizing the intensity and variety of these noise sources is only half the battle. The next step is navigating and complying with strict occupational noise exposure regulations, which form the legal and practical foundation for every effective noise control strategy in the industry.

Regulatory Standards for Mining Noise Levels

To protect miners from irreversible effects like Noise-Induced Hearing Loss (NIHL), regulatory bodies establish legally binding standards. However, the level of protection varies dramatically across the globe. In the Americas, for instance, a staggering 27% of countries still have no specific regulations for permissible noise levels, leaving millions of workers unprotected.

Understanding these regulations begins with a few core principles designed to quantify and limit a worker’s total noise dose. The two most critical components are the Permissible Exposure Limit (PEL) and the Exchange Rate (ER).

Permissible Exposure Limit (PEL)

This is the maximum average A-weighted sound level to which a worker can be exposed over a standard 8-hour workday. While limits vary, a global consensus is built around 85 dBA as the recommended best practice to prevent hearing damage.

Exchange Rate (ER)

This crucial “trading ratio” defines how allowable exposure time decreases as the noise level increases. A lower exchange rate is significantly more protective.

- 3 dB Exchange Rate: This is the scientifically preferred “equal-energy rule.” Because a 3 dB increase represents a doubling of sound energy, this standard correctly halves the permissible exposure time for every 3 dB rise.

- 5 dB Exchange Rate: A less protective standard that allows for longer exposure times at high noise levels.

Action Level (AL)

Many regulations also mandate an Action Level, typically 85 dBA, which is the threshold that triggers mandatory hearing conservation programs, including noise monitoring, audiometric testing, and training, even if the PEL is not exceeded.

The application of these principles varies significantly across the World and the Americas, creating a complex regulatory landscape for mining operations.

Mining Occupational Noise Exposure Limits in the Americas

United States (MSHA) – Mining Noise Regulations

PEL 90 dBA • ER 5 dB • AL 85 dBA

- PEL: 90 dBA

- Exchange Rate: 5 dB

- Action Level: 85 dBA

- Key Provisions: MSHA requires dual hearing protection (plugs and muffs) for exposures exceeding 105 dBA and has a strong emphasis on implementing feasible engineering and administrative controls as the primary method of noise reduction, a requirement more stringently enforced in mining than in general industry.

Canada – Mining Noise Regulations

PEL 85 dBA • ER 3 dB

- PEL: 85 dBA (federal standard is 87 dBA; Québec previously allowed 90 dBA before aligning with the 85 dBA national standard

- Exchange Rate: 3 dB

- Action Level: Not uniformly defined across all provinces/territories

- Key Provisions: Most provinces and territories impose a 140 dB peak limit for impulse/impact noise. Yukon and Northwest Territories also cap the number of daily impulses (90–100). Québec applies the 85 dBA / 3 dB standard, the 140 dB peak limit, and a daily impulse cap of approximately 100. The nationwide use of the 3 dB exchange rate provides stronger protection compared to jurisdictions still using the less protective 5 dB rate.

Mexico (STPS – NOM-011-STPS-2001) – Mining Noise Regulations

PEL 90 dBA • ER 3 dB • AL 85 dBA

- PEL: 90 dBA

- Exchange Rate: 3 dB

- Action Level: 85 dBA

- Key Provisions: Mexico pairs a higher PEL with the more protective 3 dB exchange rate. The regulation is detailed on measurement procedures but notably lacks a specific limit for impulse noise.

Latin America: Strong Regulations

Best Practice: PEL 85 dBA • ER 3 dB

Countries with Strong Regulations: Several nations have adopted the global best practice (85 dBA PEL and 3 dB ER), offering robust protection. These include:

-

- Argentina: (Resolution 295/2003)

- Chile: (Decree 594 and Technical Standard 125)

- Venezuela: (COVENIN 1565:1995 standard)

- Costa Rica: (INTE 31-09-16-00 standard)

Latin America: Weaker or Developing Regulations

Some nations: ER 5 dB

- Less Protective Standards: Countries like Brazil, Colombia, and Paraguay use the less safe 5 dB exchange rate.

Latin America: No or Limited Regulations

No specific enforceable limits

The Importance of Compliance with Noise Regulations in the Mining Industry

While regulatory standards vary across regions, strict adherence to them is critical for safeguarding workers and ensuring sustainable mining operations. Compliance is not only a legal obligation but also a strategic investment that delivers wide-ranging benefits, including:

- Improved workplace efficiency through clearer communication and fewer noise-related disruptions.

- Higher employee morale as workers feel safer and more valued.

- Reduced health-related absenteeism, lowering medical costs and compensation claims.

- Long-term profitability supported by sustained productivity and fewer operational risks.

In short, meeting or exceeding noise regulations protects hearing, strengthens workforce well-being, and enhances the overall resilience and profitability of mining operations.

Now that we have established the critical health impacts and the complex web of regulations governing mining noise, the crucial question remains: How can operations effectively comply with these standards and truly protect their workers from mining noise pollution?

How to Reduce Mining Noise Pollution: Mining Noise Control Methods

Mining Noise Control Methods: MSHA’s Priority Approach

Protecting miners from hazardous noise isn’t as simple as handing out earplugs. Effective noise control starts with a structured, proactive strategy that addresses the problem at its source.

Most industries use the hierarchy of controls to reduce workplace noise and hazards, ranking solutions from most to least effective:

- Elimination

- Substitution

- Engineering controls

- Administrative controls

- Personal protective equipment (PPE)

In mining, MSHA makes it clear: the focus must be on engineering controls and administrative controls.

- Engineering controls are physical or mechanical systems that reduce noise where it’s generated or block it along its path, often by isolating workers from the hazard.

- Administrative controls reduce exposure by modifying work practices and schedules rather than changing the equipment itself.

Why not elimination, substitution, or PPE?

- Elimination and substitution are rarely feasible in mining. By design, drilling, blasting, and crushing are loud processes.

- PPE alone is never enough under MSHA’s noise rule (30 CFR Part 62). It’s the last line of defense, not a standalone solution.

In short, MSHA’s stance is clear: you can’t eliminate the noise of mining, but you can control it. That control starts with engineering solutions that quiet the source or block the sound, supported by administrative strategies that limit exposure, and, only when necessary, PPE as a final safeguard.

The following sections break down each layer of this protection strategy — from physically reducing noise in the mine to managing work practices and ensuring workers have the right personal protection when all else has been done.

Engineering Controls — Reducing Mining Noise Pollution at the Source and Path

Engineering controls are physical or mechanical solutions that directly reduce mining noise pollution where it’s generated or block it before it reaches workers.

Engineering controls deliver long-term, reliable noise reduction in mining operations without relying on worker behavior. Examples of engineering controls in mining:

Acoustic enclosures and barriers around crushers, mills, and fans to contain high-decibel noise and limit occupational noise exposure.

Control rooms and operator cabins for isolating workers near operations. (picture on the left)

Silencers and mufflers on ventilation systems, exhausts, and pneumatic drills to dampen high-frequency sound.

Vibration isolation mounts to reduce structure-borne noise from heavy machinery.

Low-noise component upgrades, such as composite fan blades or redesigned drill bits.

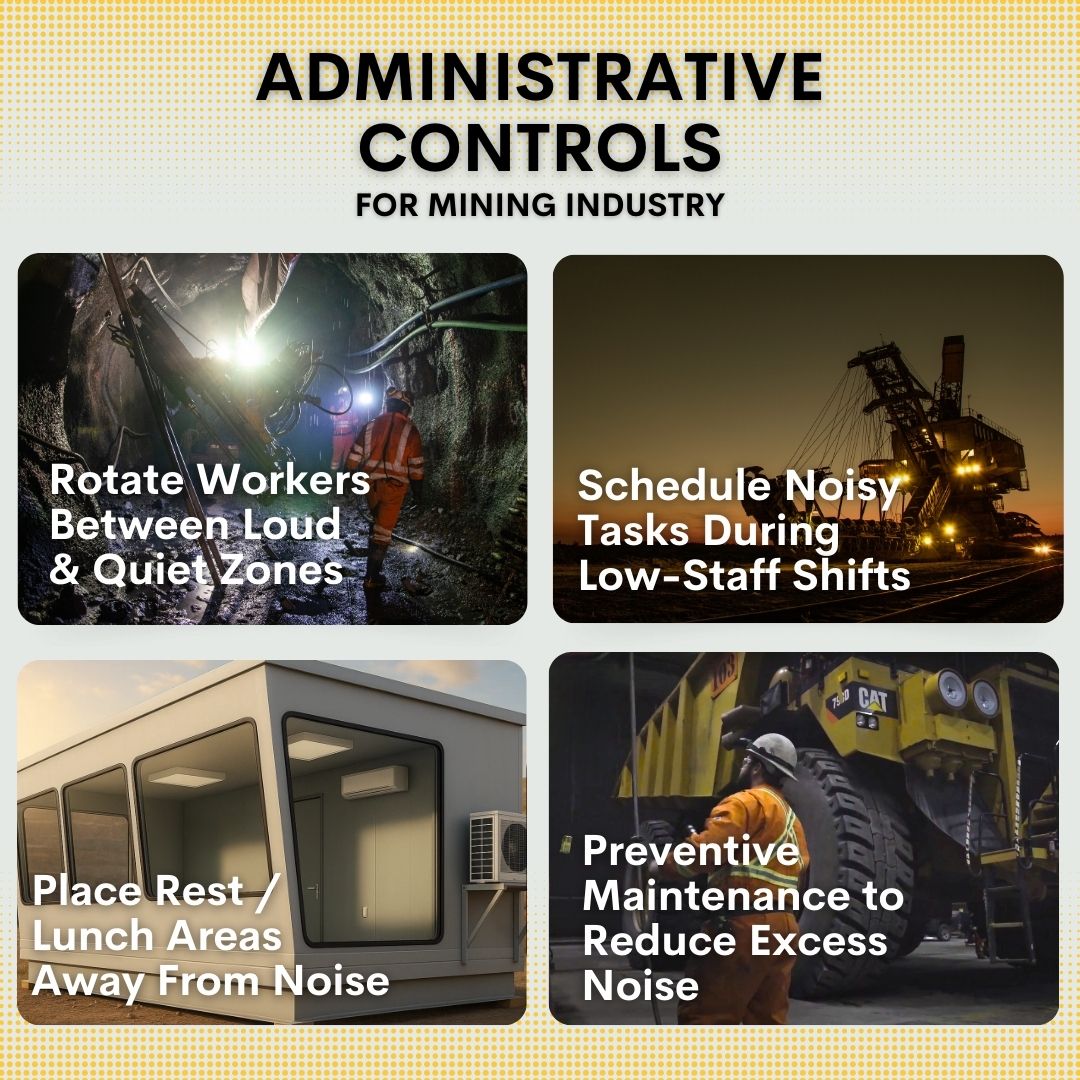

Administrative Controls — Managing Mining Noise Exposure Through Work Practices

Administrative controls don’t make equipment quieter, but they reduce the amount of time a worker is exposed to harmful occupational noise in mining environments. These measures are most effective when combined with engineering solutions to achieve compliance and protect hearing. Examples in mining:

Worker rotation between high-noise and quieter areas to reduce overall noise exposure.

Scheduling noisy activities during shifts with fewer personnel present.

Repositioning rest areas and control rooms away from the primary noise sources.

Preventive maintenance programs to stop excess noise caused by worn or loose components.

Personal Protective Equipment (PPE) — The Last Line of Defense Against Mining Noise Pollution

When all feasible engineering and administrative controls have been implemented and mining noise exposure still exceeds the Permissible Exposure Limit (PEL), PPE becomes mandatory.

PPE helps protect the ear but does not solve the root cause of mining noise pollution, so it should always be used alongside other noise control measures. Examples in mining:

Earplugs for moderate noise exposure.

Earmuffs or dual protection (earplugs + earmuffs) for environments above 105 dB.

Custom-molded earplugs for comfort and consistent attenuation during long shifts.

This layered approach sets the foundation for effective noise control — but seeing it in action makes the impact clearer. The next section highlights a real-world example of how a mining operation used targeted engineering controls to drastically reduce exposure to mining noise pollution and protect its workers.

Featured Case Study

Conclusion: Making Mining Quieter, Safer, and More Sustainable

Mining noise pollution is one of the industry’s most persistent and underestimated hazards. It silently erodes worker health, disrupts communities, and impacts the environment — yet it is entirely possible to control.

The solution lies in a layered approach: start by reducing noise at the source with engineering controls, reinforce with administrative measures that limit exposure, and use PPE as the final safeguard. This isn’t just MSHA’s regulatory mandate — it’s a proven strategy for protecting people and maintaining productivity.

Across the globe, forward-thinking mining operations are proving that effective noise control is both technically achievable and economically smart. By investing in quieter equipment, acoustic enclosures, operator cabins, and proactive work practices, mines can prevent hearing loss, improve morale, and safeguard their social licence to operate.

Mining will never be silent, but it doesn’t have to be deafening. The tools, technologies, and strategies exist — and the sooner they’re implemented, the sooner we can ensure a safer, healthier, and more sustainable future for workers, communities, and the environment.

Build Your Mining Noise Control Strategy

Use our checklists to start designing your acoustic enclosure or modular engineering control—or request a budgetary estimate for your site.

RESOURCES

McBride, D. I. (2004). Noise-induced hearing loss and hearing conservation in mining.

Occupational Medicine, 54(5), 290–296.

https://doi.org/10.1093/occmed/kqh075

Domingo-Pueyo, A., Sanz-Valero, J., & Wanden-Berghe, C. (2016). Disorders induced by direct occupational exposure to noise: Systematic review.

Noise & Health, 18(84), 229–239.

https://pmc.ncbi.nlm.nih.gov/articles/PMC5187650/

Golmohammadi, R., & Darvishi, E. (2020). The combined effects of occupational exposure to noise and other risk factors: A systematic review.

Noise & Health, 21(101), 125–141.

https://pmc.ncbi.nlm.nih.gov/articles/PMC7650855/

Gannouni, N., Wang, J., Ben Rhouma, K., & Mhamdi, A. (2024). Human health effects associated with occupational and environmental acoustic trauma.

Health Sciences Review, 12, 100181.

https://doi.org/10.1016/j.hsr.2024.100181

Mehrotra, A., Shukla, S. P., Shukla, A. K., et al. (2024). A comprehensive review of auditory and non-auditory effects of noise on human health.

Noise & Health, 26(121), 59–69.

https://pmc.ncbi.nlm.nih.gov/articles/PMC11530096/

Sordello, R., Ratel, O., De Lachapelle, F. F., Leger, C., Dambry, A., & Vanpeene, S. (2020).

Evidence of the impact of noise pollution on biodiversity: A systematic map.

Environmental Evidence, 9, Article 20.

https://environmentalevidencejournal.biomedcentral.com/articles/10.1186/s13750-020-00202-y

Moffat, K., & Zhang, A. (2014). The paths to social licence to operate: An integrative model explaining community acceptance of mining.

Resources Policy, 39, 61–70.

https://doi.org/10.1016/j.resourpol.2013.11.003

Arenas, J. P., & Suter, A. H. (2014). Comparison of occupational noise legislation in the Americas: An overview and analysis.

Noise & Health, 16(72), 306–319.

https://doi.org/10.4103/1463-1741.140511

Canadian Centre for Occupational Health and Safety. (n.d.).

Noise – Occupational exposure limits.

https://www.ccohs.ca/oshanswers/phys_agents/noise/exposure_can.html

Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. (n.d.).

Hearing loss prevention in mining.

https://www.cdc.gov/niosh/mining/topics/hearing-loss.html

Lawson, S. M., Masterson, E. A., & Azman, A. S. (2019). Prevalence of hearing loss among noise-exposed workers within the mining, and oil and gas extraction sectors, 2006–2015.

American Journal of Industrial Medicine, 62(10), 826–837.

https://doi.org/10.1002/ajim.23031

Seiler, J. P., & Pon, M. (n.d.).

Engineering and administrative noise controls for the mining industry

[Technical paper, U.S. Department of Labor, Mine Safety and Health Administration]. (Publisher/venue not specified).

Babich, D. R., & Bauer, E. R. (n.d.).

Summary of longwall and continuous miner section noise studies in underground coal mines.

National Institute for Occupational Safety and Health (NIOSH), Pittsburgh Research Laboratory. [Technical summary].

Government of Ontario. (n.d.). Appendix D: Noise in construction, mining, farming and firefighting operations

(Guide to the Noise Regulation under the Occupational Health and Safety Act).

https://www.ontario.ca/document/guide-noise-regulation-under-the-occupational-health-and-safety-act/appendix-d-noise-construction-mining-farming-and-firefighting-operations

Amosu, C. O. (2021). Effects of noise and control in mine operation.

Indian Journal of Petroleum Engineering (IJPE), 1(2).

https://doi.org/10.54105/ijpe.B1903.111221

Mine Safety and Health Administration (MSHA). (2014, March 7).

Program Information Bulletin No. MSHA-P14-02: Reissue of P08-12—Technologically Achievable, Administratively Achievable, and Promising Noise Controls (30 CFR Part 62).

U.S. Department of Labor.