Modular Inplant Offices

Whether for a conference room, lunch room, rest room, or factory office, MECART modular inplant offices and prefab buildings allow workers to have a safe and quiet place, isolated from noisy environments and dangers in the factory.

Take Control of Noise—Start Protecting What Matters Most

Engineered for Industrial Success: MECART Modular In-Plant Offices

MECART’s modular in-plant offices deliver superior soundproofing, durability, and tailored solutions for noise and hazard control. Designed for compliance and comfort, they feature options like ventilation, fire resistance, and integrated utilities. Scalable and ergonomic, they adapt to your space – ensuring a productive, safe, and customizable workspace.

In-Plant Offices That Control Noise for Safer, Healthier Workspaces

Industrial noise isn’t just disruptive—it’s a health risk. MECART’s modular in-plant offices reduce noise exposure, creating safer and more productive environments. Your team can focus better, communicate clearly, and avoid noise-related health risks—all while staying close to operations.

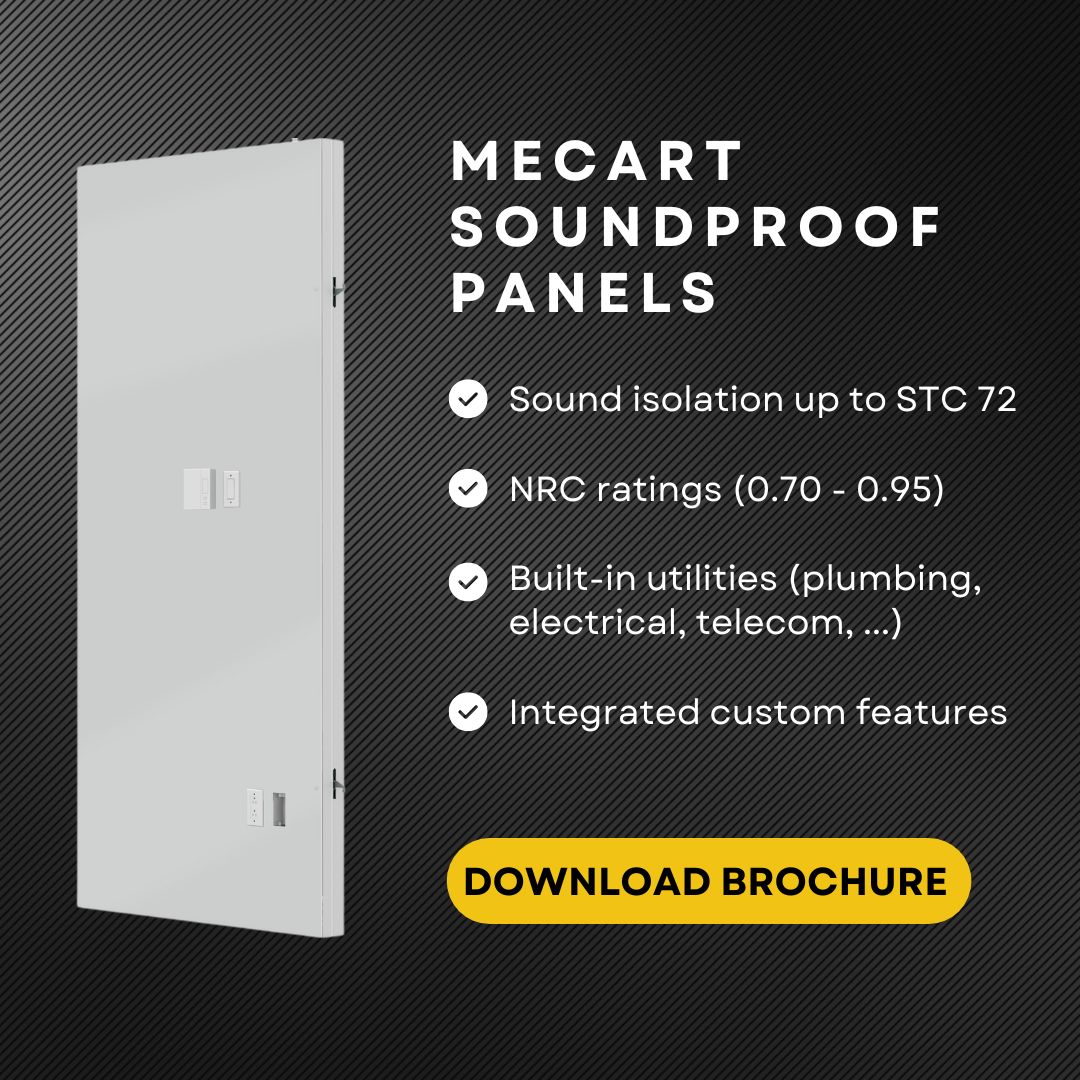

Premium Soundproofing – Up to STC 72

With soundproofing levels from STC 35 to STC 62—and up to STC 72 with a double-wall configuration—our in-plant offices create quiet, functional spaces that protect workers and meet stringent safety standards

Built for Compliance – Modular Inplant Offices That Protect Your People & Equipment

Protect your most valuable assets with MECART in-plant offices and meet the strictest occupational health and safety standards (OSHA, NIOSH, CCOHS).

Apart from noise, workers face a range of daily health risks. Hazard mitigation features can be added to the design of your inplant offices.

- Ventilation

- Dust collection

- Fire-resistant materials

- Chemical-resistance

- Waterproof membranes

- Reinforced structures

- UV resistance

- Other specialized features

Heavy-Duty, Long-Lasting Modular In-Plant Offices

Crafted with two sheets of 16-gauge galvannealed steel, MECART’s 4-inch-thick panels are engineered for durability. Designed to withstand impacts, resist corrosion, and handle demanding conditions, these panels are built to last.

➡️Resistant to impacts, collisions, and corrosion

➡️Built to endure industrial, harsh indoor or outdoor environments

➡️Engineered to maintain their durability for over 25 years

Cut the Noise with MECART Modular Inplant Offices

Integrated, Scalable & Ergonomic: MECART Modular Inplant Office System

MECART modular in-plant offices provide a comprehensive solution designed to optimize comfort, functionality, and adaptability within your facility. With advanced integrations, ergonomic designs, and a scalable modular design, our inplant offices ensure easy installation and operational efficiency.

Advanced Air Quality and Climate Control

Our modular offices feature custom HVAC systems to maintain ideal working conditions – protecting equipment and operators.

Comfortable Work Environments: Ensure a temperate and productive workspace for your team

Superior Air Quality: Enjoy enhanced air circulation and filtration, even in challenging industrial environments

”The design, the quality, the soundproof, the dustproof feature, all the climate control, the quality was top notch and exceeded our expectations” – Chad Withfield, Plant Manager at Canfor

Space Optimization and Scalability

Maximize your facility’s potential with modular designs that adapt to your space and operations:

Stackable up to Three Stories: Make the most of vertical space for increased efficiency

Elevated Oversight: Gain enhanced visibility over factory operations with elevated structures

Flexible Placement: Install at ground level or on a mezzanine to fit your facility’s layout

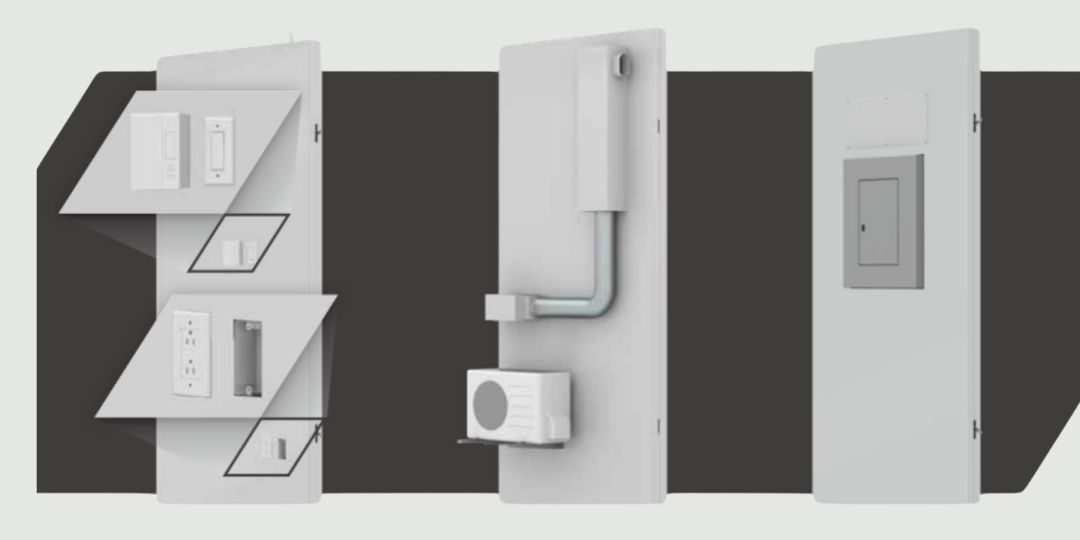

Built-in Integrations for Streamlined Operations & Installation

Our prefabricated panels are equipped with fully integrated utilities, tailored to meet your operational needs. Ask our experts for custom features.

Electrical & Mechanical Systems: Pre-wired outlets and lighting fixtures for immediate use

Plumbing Options: Piping and accesses are built-in, inside the panels. We can even provide and install toilets, sinks, showers, drains, for a complete turnkey solution

Telecommunications: Seamless internet and phone connectivity to keep your operations running smoothly

Tailored Design for Your Facility

MECART modular offices are engineered to integrate seamlessly into your workspace, accommodating your unique operational environment and requirements. Key features include:

Angled Windows: Improve visibility while reducing glare for enhanced comfort

Ergonomic Design Elements: Adjustable layouts, optimized workflows, furniture, noise-reducing materials, and customizable features

Positioning Near Challenges: Engineered to perform near hazards, at the heart of operations – our in-plant offices can be placed near heat sources, noisy machinery, or vibrating equipment

Upgrade Your Workspace with MECART Modular In-Plant Offices

More Than Just In-Plant Offices – Ideal for Any Type of Modular Rooms

Conference Rooms

To preserve a comfortable and quiet place for your meetings, even in the midst of the action of the factory!

Rest Rooms, Locker Rooms, Lunch Rooms

Countertops and cabinets in laminate, stainless steel or melamine, complete plumbing, preparation for refrigerators, microwave and toaster racks, lockers, cabinets … There is no limit to the interior design of our modular buildings.

Bathroom / Shower

A room with toilets and showers can be attached to any MECART modular building. All types of plumbing equipment can be included: toilet, shower, washbasins, bathroom accessories, etc.

Factory / In-Plant Offices

The walls have the necessary services built right into them, including telecommunication outlets (internet, telephone). An electrical gutter can be added to allow quick and easy connection of your cables. Office furniture can also be provided.

Modular or Pre-Assembled – 2 Ways to Have Your Modular Inplant Office Delivered

We offer two assembly options: the prefabricated modular panels can either be shipped unassembled on-site, or fully preassembled at MECART’s plant and delivered in a single module for a plug & play option.

Field Install: Modular Inplant Office Panels Assembled On-Site

1. The prefabricated panels are delivered on skids at your site

2. Easy install by our install team or 3rd party thanks to our panel interlocking system

3. Ideal if the pre-assembled in-plant offices or modular rooms cannot fit through your building doors or if you have a smaller budget. Discover how we delivered SiriusXM studio through their 2nd floor windows

Plug-And-Play Install: Prefabricated Modular Inplant Offices

1. The in-plant office is assembled at MECART’s plant in 1 or 2 units, depending of size

2. The design includes a reinforced structure with lifting rings, allowing the prefab unit to be easily lifted, loaded onto a truck, and shipped to your location

3. Just power up the pre-assembled inplant office and it’s ready for use