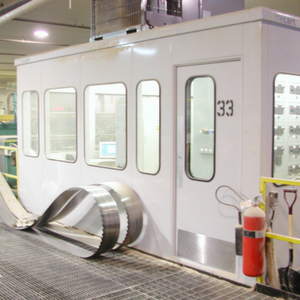

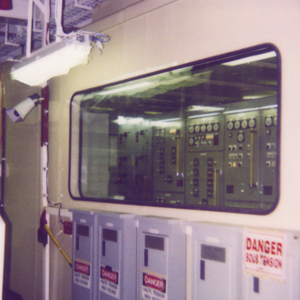

Protect your Equipment Against Hazards

MECART’s E-houses are specially designed to withstand extreme environmental conditions: corrosive environments, extreme temperatures, high humidity, extreme levels of air-latent particulates and excessive vibrations. All materials used are non-combustible. To optimize durability, special attention is paid to waterproofing, airtightness and resistance to corrosion. The structural performance of our products follow building codes, ISO 9001, and are resistant to wind, snow, salt environments and seismic conditions.