What Are the Main Characteristics of Industrial Noise?

Industrial noise is more than just an unpleasant sound. It results from how sound is produced, transmitted, and behaves in a specific environment.

Here are the key characteristics of industrial noise that are crucial to grasp for effective noise control and management:

1. Noise Levels (dB) – Intensity of Sound

Industrial noise can range from moderate levels (~60-70 dB), similar to an air conditioning unit at 100 feet, to extreme levels (100+ dB) found in heavy industries. Prolonged exposure to noise levels above 85 dB may lead to hearing damage, while noise exceeding 120 dB can cause immediate harm.

2. Frequency (Hz) – Sound Profile

Low-frequency noise, like rumbling or humming, can travel long distances and penetrate barriers, making it difficult to control. High-frequency noise, such as whining or screeching, is more irritating over time but easier to block with sound barriers.

3. Duration & Exposure – Noise Patterns

- Continuous noise: Comes from machinery operating nonstop, like conveyor belts or ventilation systems

- Intermittent noise: Starts and stops, such as drilling or stamping

- Impulsive noise: Sudden bursts, like hammering or explosions

4. Vibrations – Impact on Structures

Industrial noise often produces mechanical vibrations, which not only amplify sound but can also weaken building structures and equipment over time. These vibrations can lead to structural fatigue, equipment malfunctions, and increased maintenance costs.

5. Noise Propagation & Reflection – How Sound Spreads

Noise spreads differently depending on the environment. In open spaces, sound dissipates faster, while in enclosed areas, reflections from hard surfaces increase echoes and reverberation, raising overall noise levels.

6. Directionality – Noise Sources

- Point source noise: Comes from a single source, like a generator

- Line source noise: Emitted along a length, such as pipelines or conveyor belts

- Diffuse noise: Originates from multiple sources, every noise sources of an entire factory floor, creating a complex and unique noise environment

Industrial Noise Regulations and Workplace Safety Standards

Protecting workers from industrial noise and workplace noise pollution is a top priority for regulatory bodies worldwide. These organizations have established clear noise exposure limits, guidelines, and recommendations to safeguard employees’ hearing and overall well-being. Employers are required to monitor workplace noise levels, implement noise control measures, and provide hearing protection when necessary.

We’ll break down the key regulatory bodies and workplace noise standards, covering organizations like the World Health Organization (WHO), OSHA, NIOSH, and ESDC. We’ll also explain noise exposure guidelines, permissible exposure limits (PEL), and compliance requirements to help you better understand how to manage industrial noise in the workplace.

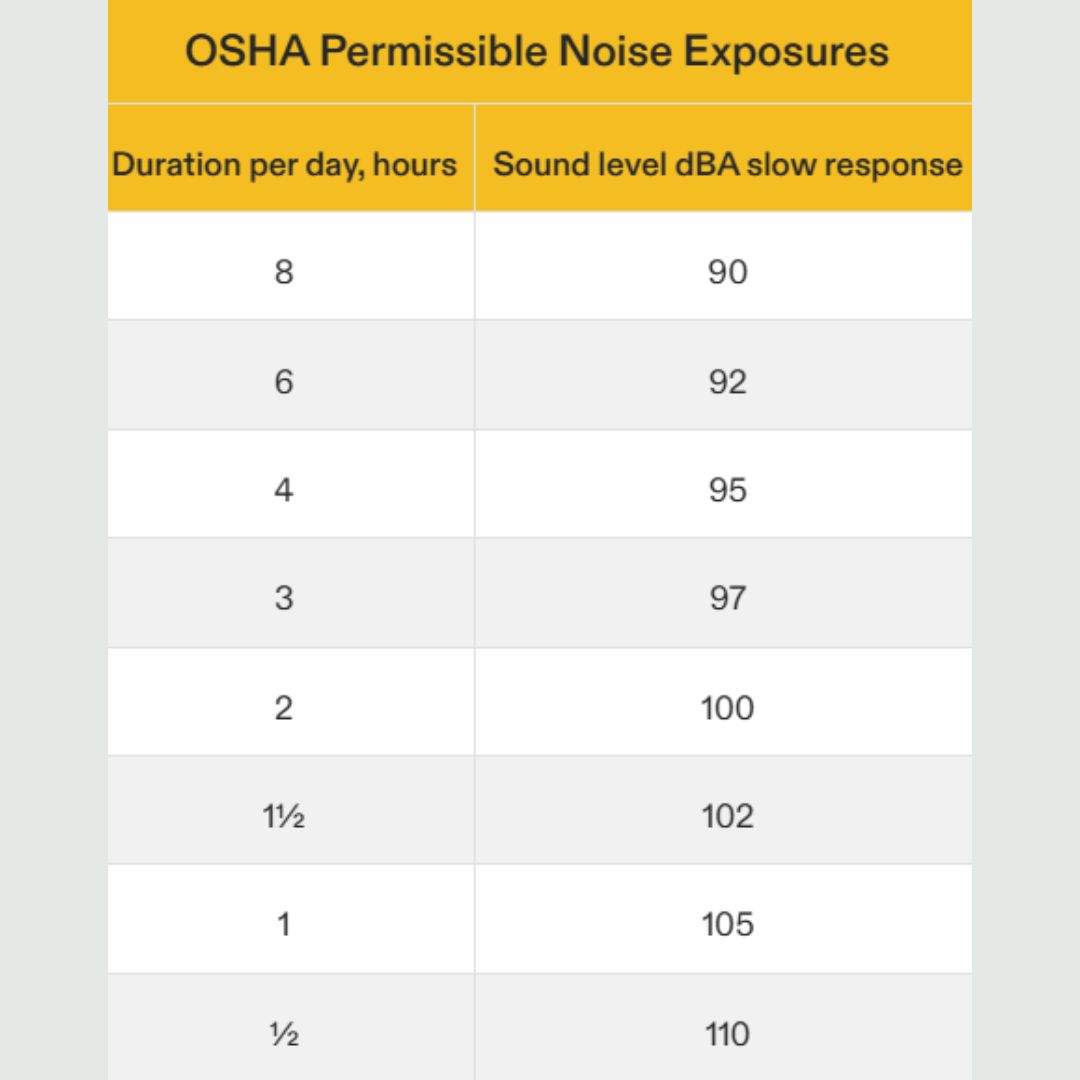

1. OSHA and NIOSH Noise Standards (USA)

a. Occupational Safety and Health Administration (OSHA)

OSHA, a U.S. federal agency, enforces workplace safety regulations, including industrial noise limits.

- Permissible Exposure Limit (PEL): 90 dB(A) over an 8-hour TWA.

- Action Level: 85 dB(A) over an 8-hour TWA, requiring a Hearing Conservation Program.

- Exchange Rate: 5 dB—for every 5 dB increase in noise, the permissible exposure time is halved.

- Source: OSHA – Occupational Noise Exposure

b. National Institute for Occupational Safety and Health (NIOSH)

NIOSH, part of the CDC, conducts research and provides safety recommendations, including industrial noise control.

- Recommended Exposure Limit (REL): 85 dB(A) over an 8-hour TWA.

- Exchange Rate: 3 dB—for every 3 dB increase, exposure time is halved.

- Source: NIOSH – About Occupational Noise

2. World Health Organization (WHO) Noise Guidelines

The World Health Organization (WHO) provides global recommendations to protect public health, including workplace noise standards.

- Permissible Noise Level: WHO recommends a maximum noise exposure of 85 dB(A) over an 8-hour time-weighted average (TWA) to minimize the risk of hearing loss.

- Why it Matters: Prolonged exposure to unsafe noise levels can lead to irreversible hearing damage.

- Source: WHO – 1.1 Billion People at Risk of Hearing Loss

3. Employment and Social Development Canada (ESDC)

The ESDC oversees workplace health and safety under the Canada Labour Code.

- Noise Limit: 87 dB(A) over an 8-hour TWA.

- Employer Requirements: Implement noise control measures and provide hearing protection if noise exceeds limits.

- Source: Levels of Sound – Canada Occupational Health and Safety Regulations, Part VII

Need Guidance on Compliance and Control Measures?

Industrial Noise Exposure: Examples by Industry

How Loud is Loud?

To put noise levels into perspective, a normal conversation typically measures around 60–70 dB. However, sound intensity doesn’t increase in a simple, linear way—it multiplies:

- 80 dB is twice as loud as 70 dB

- 100 dB is 16 times louder than 60 dB

Industrial Noise Levels Across Industries

Industrial noise levels can vary widely depending on factors such as machinery type, operational processes, and proximity to noise sources. While actual noise levels differ between facilities, scientific studies provide useful benchmarks to estimate typical sound levels in different work environments.

Below, we outline common noise levels found in various industries. These figures serve as a general reference based on research samples and may not reflect the exact conditions of every workplace.

For detailed sources, refer to the end of this article.

dB Range: 69–118 dB

dB Range: 78–106 dB

dB Range: 71–110 dB

dB Range: 81–100 dB

dB Range: 81–98 dB

dB Range: 63-115 dB

dB Range: 88-94 dB

dB Range: 73-115 dB

dB Range: 86-96 dB

dB Range: 70-120 dB

dB Range: 81-110 dB

dB Range: 69-103 dB

Industrial Noise Control Solutions: How to Minimize Noise in the Workplace

Industrial noise is a common challenge in many workplaces, especially in industries that rely on heavy machinery. Managing noise levels is crucial for protecting employees from hearing damage and ensuring compliance with workplace safety regulations. This guide outlines effective industrial noise control methods to help businesses reduce noise exposure and create a safer work environment.

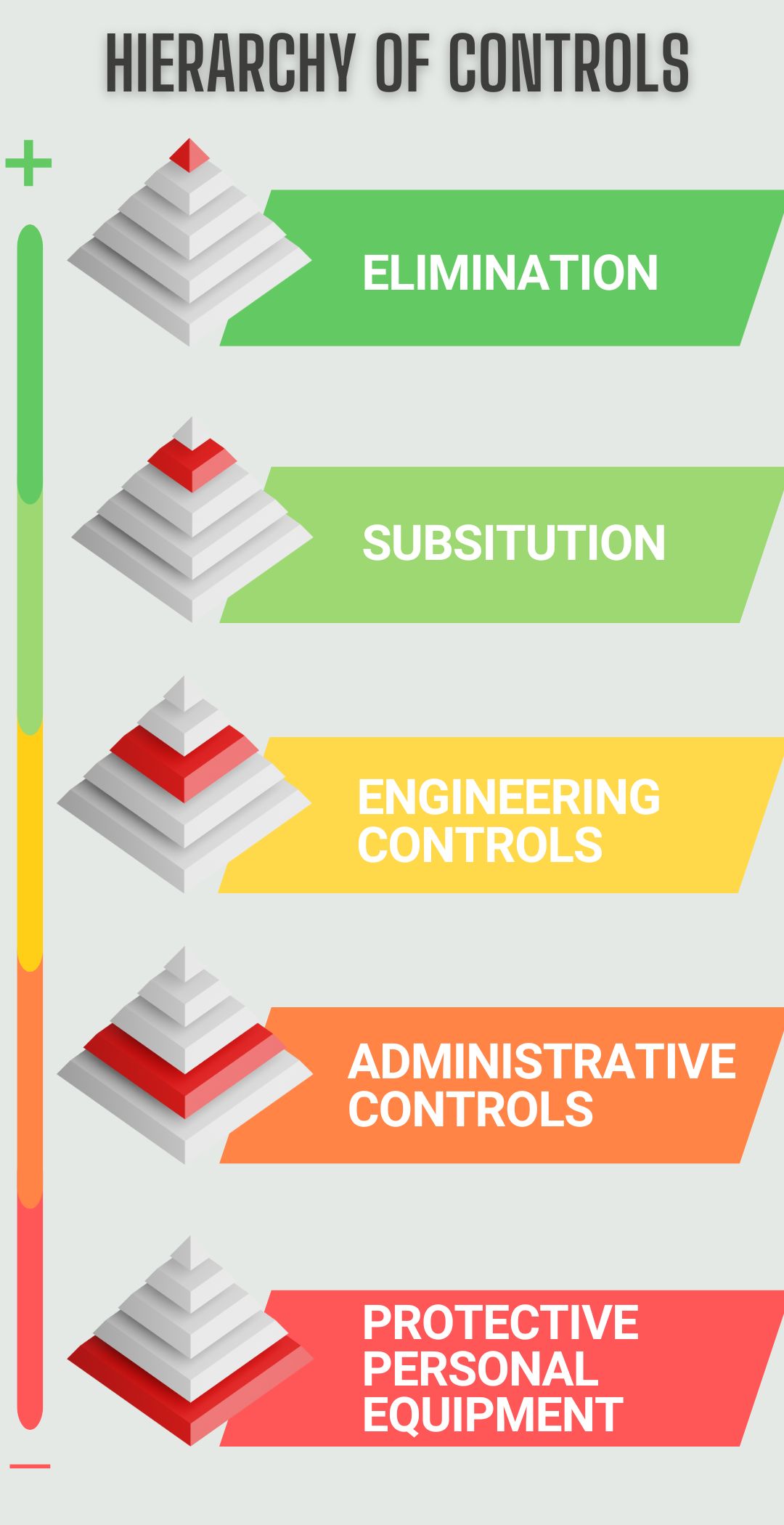

What Are the Best Ways to Control Industrial Noise?

Effective industrial noise control typically follows a hierarchy of strategies. These include eliminating noise at the source, substituting quieter equipment, implementing engineering controls, and using administrative controls and personal protective equipment (PPE). Below, we explore each of these methods in detail.

1. Eliminate Noise at the Source

The most effective way to control industrial noise is to eliminate its source. When that’s not possible because operations rely on noisy, heavy machinery, consider redesigning workflows or automating processes to minimize manual operation and reduce noise exposure.

2. Substitute Noisy Equipment with Quieter Alternatives

When elimination isn’t feasible, replacing noisy machinery with quieter models is a great option. Using alternative materials or equipment designed to produce less noise can significantly lower decibel levels in the workplace.

3. Use Engineering Controls for Industrial Noise Reduction

Engineering controls are one of the most effective ways to manage industrial noise. These methods address noise at its source or create barriers to protect workers. Examples of engineering controls include:

- Installing acoustic enclosures around loud machinery to contain noise

- Isolating operators inside acoustic control rooms, in-plant offices, or operator cabins

- Setting up noise barriers between the noise source and workers

These solutions are ideal for balancing cost-effectiveness with long-term noise reduction.

4. Implement Administrative Noise Control Measures

Administrative controls focus on adjusting workplace procedures to manage noise exposure. These strategies can include:

- Scheduling noisy maintenance tasks during non-operational hours

- Rotating employees through quieter job tasks to minimize prolonged exposure to loud environments

5. Provide Personal Protective Equipment (PPE)

As the last line of defense, providing PPE such as earmuffs or foam earplugs is essential for protecting workers from excessive noise. While PPE is less effective than engineering or administrative controls, it is a necessary backup when other methods cannot fully eliminate noise exposure.

Why a Multi-Faceted Approach to Industrial Noise Control Is Essential

No single noise control method is guaranteed to offer complete protection. Instead, businesses should layer multiple strategies to ensure comprehensive industrial noise control and management. For example:

- Engineering controls can address noise at the source

- Administrative controls help limit worker exposure through scheduling and task adjustments

- PPE provides additional protection for employees in high-noise environments

By combining these approaches, businesses can significantly reduce noise risks, protect employees’ hearing, and comply with workplace safety standards.

Effective Industrial Noise Control Solutions – Case Studies

Example 1: Control Rooms for Industrial Noise Reduction – 39 dBA Decrease

Rio Tinto Alcan implemented a modular control room with STC 45 soundproofing at one of its aluminum smelters. This innovative solution protects workers from dangerous industrial noise, which can exceed 100 dBA during smelting operations.

The control room reduces noise levels by 39 dBA, bringing them well below the safety threshold of 85 dBA for prolonged exposure. This not only protects workers’ hearing but also creates a safer and more comfortable workplace.

If you’re considering an acoustic control room to isolate your operators, download the control room design checklist to guide you through the process.

Example 2: Noise Enclosures for Power Transformers – Up to 28 dBA Reduction

The Appalaches-Maine Interconnection project faced strict community noise regulations, requiring sound levels near residential areas to stay between 40-45 dBA. Power transformer noise, however, reached nearly 100 dB, posing a significant challenge.

To meet these regulations, custom acoustic enclosures were installed around the transformers. These enclosures reduced noise by 20 dBA at 120Hz and 28 dBA at 400Hz, directly at the source. This solution ensured compliance, protected nearby communities, and supported sustainable development goals.

Example 3: Noise Barrier in Textile Plant – From 110 dB to Below 85 dBA

A textile plant required a noise barrier to separate two production areas, where machines produced 110 dB at 700 Hz.

To create a safer workspace, noise levels needed to be reduced below 85 dB while still allowing products to pass through.

The solution to effectively control the noise was a 24′ x 100′ modular acoustic wall, built with perforated steel acoustic panels on one side for sound absorption and noise mitigation.

The modular approach provided a better lead time for the client, with a cleaner and faster installation at the client site.

Industrial Noise Control: Time to Take Action

The hum of modern industry signals progress, but it comes at a cost—persistent noise pollution that disrupts communities, harms ecosystems, and affects workers’ well-being. It’s not just about noise; it’s about real consequences—lower productivity, health issues, and strained resources.

But this isn’t inevitable. With the right tools and actions, we can reduce noise through smarter engineering and better worker protections. This means safer, healthier workplaces, calmer neighborhoods, and a better balance between industry and nature. Let’s design a tailored industrial noise solution that works for your industry.

Industrial Noise Issues in Your Plant?

MECART’s industrial noise solutions are custom-engineered to meet your needs. Our experts design and build engineering controls that ensure compliance and protect your workers.