Custom Control Rooms: Build the Control Room Best Adapted to Your Environment

A global leader in energy sector pipe manufacturing approached us to integrate control rooms into their LEED-certified facility, meeting unique requirements and blending seamlessly with existing equipment—beyond the capabilities of standard solutions.

Standard solutions often fall short, fulfilling only a few criteria and necessitating extensive retrofits – Our client needed one single turnkey solution, a one-stop shop for custom control rooms that checked all boxes without compromise. With over 50 years of expertise in manufacturing tailored controlled environments and industrial noise control solutions, MECART was the perfect fit.

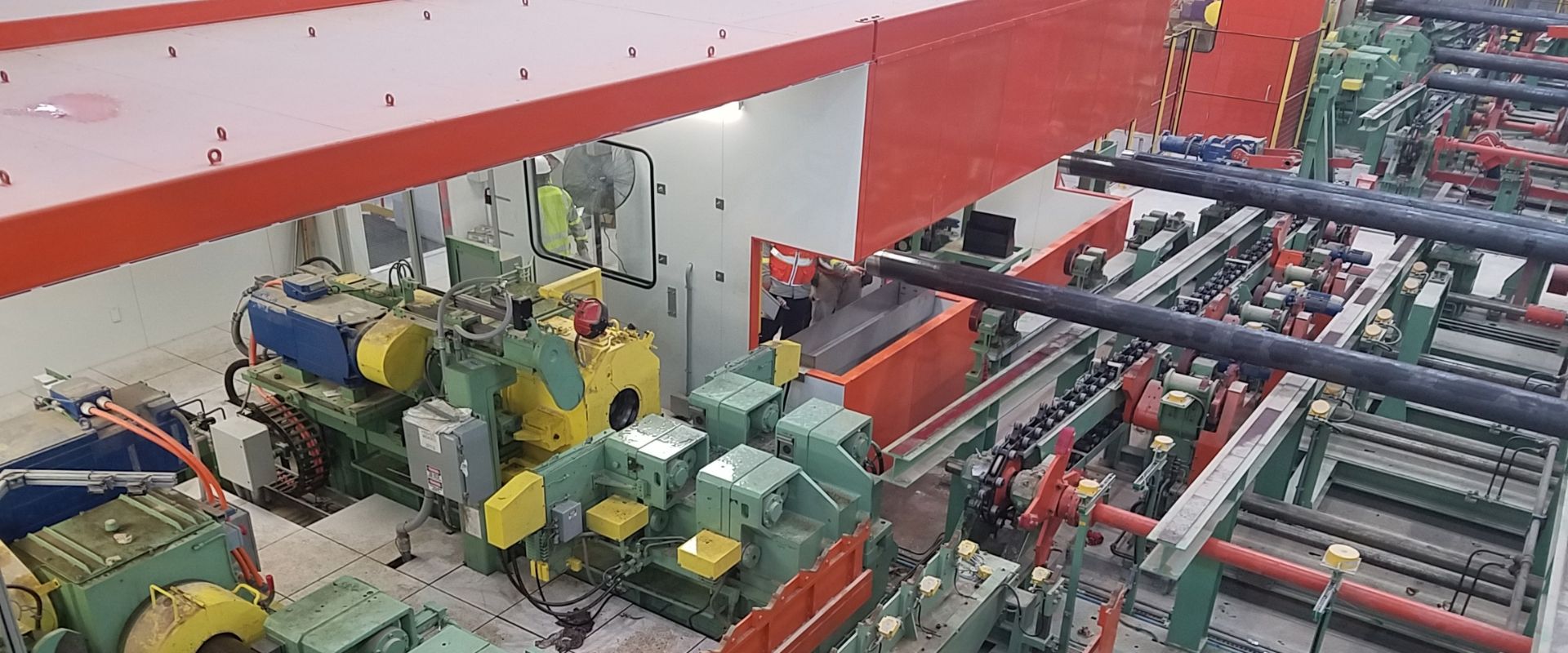

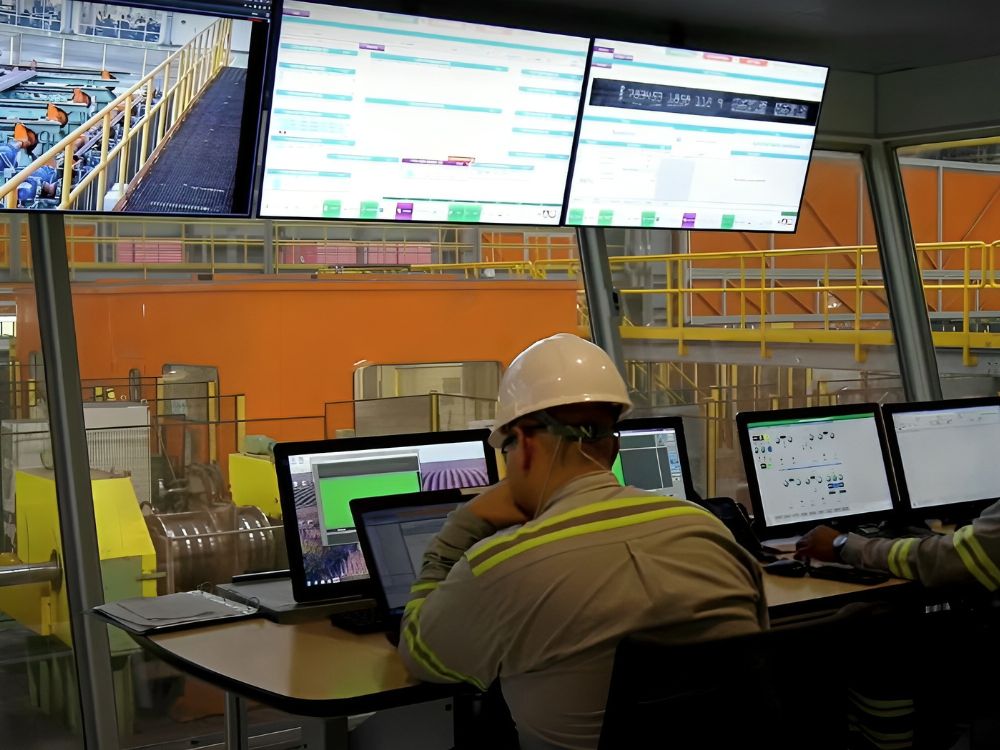

For their Texas-based pipe manufacturing facility, we designed and built custom control rooms to oversee their pipe threading machine operations, incorporating:

- Premium soundproofing tailored to their unique noise sources and levels

- Custom size fit to match their exact needs within the available space

- Custom raised floor for efficient utility and cable management

- Custom ergonomic layout boosting operator comfort, productivity, and focus

- Custom color to match the company’s branding

MECART offers complete customization for your control room, engineered to your specific needs. Whether it’s climate & air quality control (HVAC), window/door selection, superior soundproofing, easy-access maintenance panels, UV resistance, or any other feature you require, our engineers can make it happen.